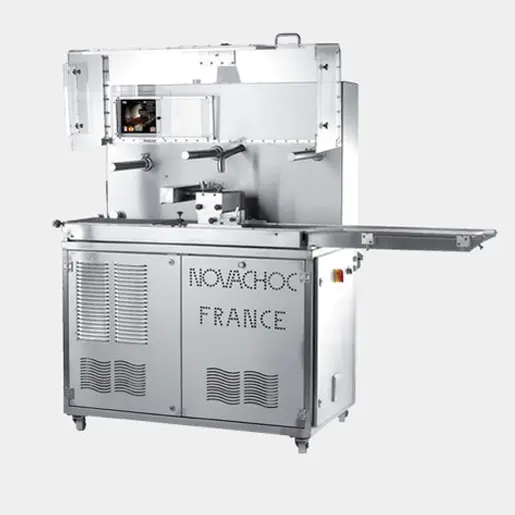

Tempering and enrobing machine TE4

Temperature adjustment under hood with possibility of orientation of three flows.

Stainless steel machine

Three-phase refrigeration unit, blower variator and heated work surface

Tank capacity: 75 kg with tank level detector

Closed circuit (without water inlet)

Electrical supply 380V (3Ph+N+T) - possibility of different electrical supply

Start-up system for tempering

Hood with adjustable ambient heating (opening/closing by pneumatic actuator)

Chocolate temperature controlled by PID system with PT100 probe

Possible chocolate supply during use

Crystallization time: about 60 min (depending on the temperature of the chocolate)

Modem for remote customer service connection

Touch screen functions

Easy to use, the touchscreen provides additional functions:

- Delayed start programming with temperature control activation

- Programming the alternating operation of the mixer during the melting of the chocolate

- Recording of programmes by recipe/by coverage

- Programming of automatic standby (with the option to activate the mixer alternately)

- Alarm function - displays the fault (example: safety grille removed)

Overlay carpet

Coating with double netting

Blower with variable speed drive

Conveyor speed controller

Detection cell for automatic carpet stop

Possibility to stop the loading grid

Possibility to separate the grille from the exit mat

Loading grid length 1100 mm and coating grid length 858 mm

Coating grid width 300 mm

Length of the exit conveyor of 2600 mm

Width (mm)

1300Height (mm)

2000Width (mm)

340Working height (mm)

1070Depth (mm)

800Weight (kg)

460Length (mm)

4558Weight (kg)

55Tempering machine

The carpet

Size

Other products

Discover what's new